Operations Monitoring

Strive for best-in-class productivity metrics to boost revenue

Value Proposition

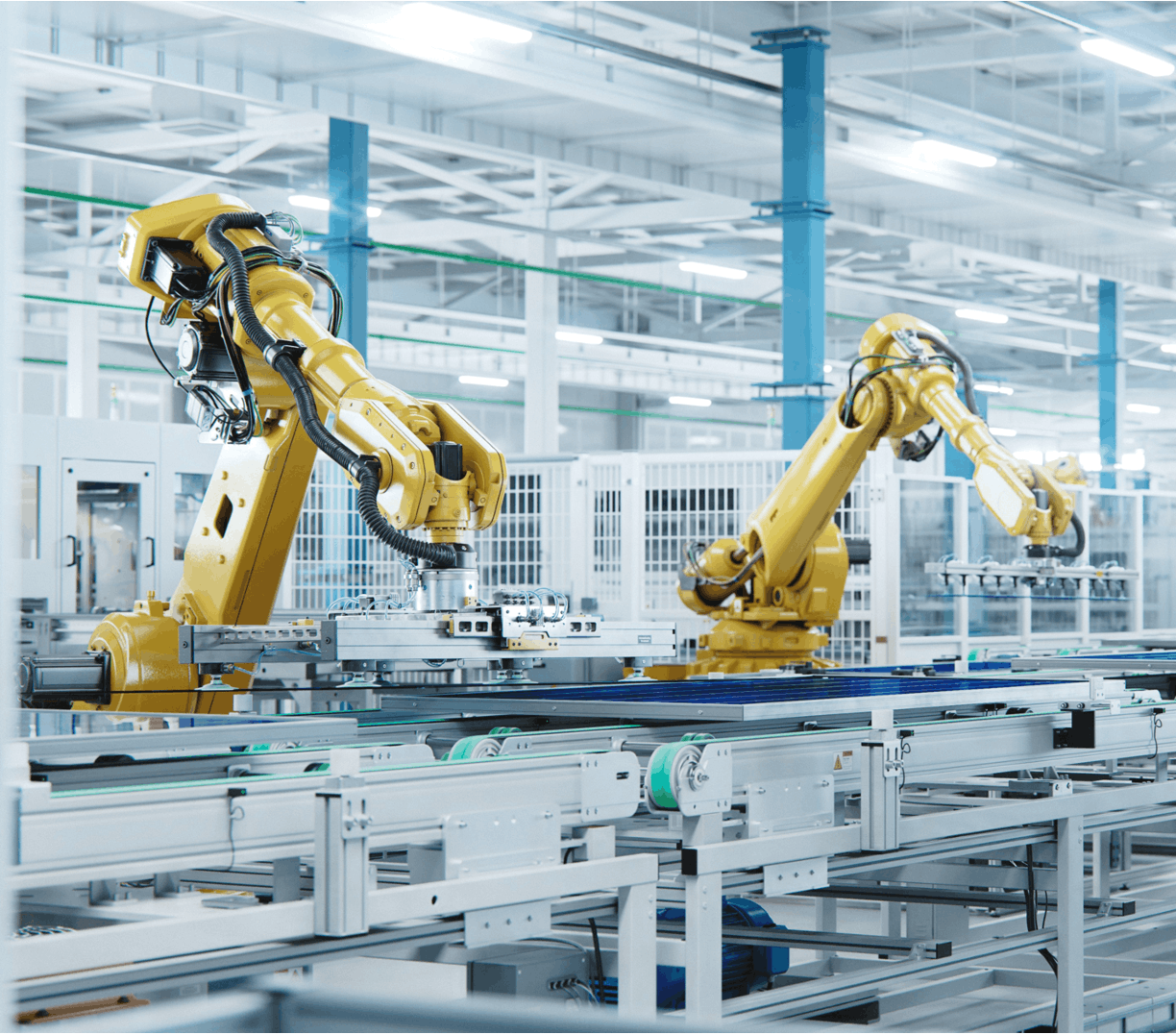

Our next-generation data capture solution aligns with your activity key performance indicators, empowering operational teams to iterate faster on their manufacturing processes. Through precise tracking of faulty parameters, early detection of inefficiencies, and swift identification of potential issues, we enable optimized operations, reduced downtime, and an improved overall production yield rate.

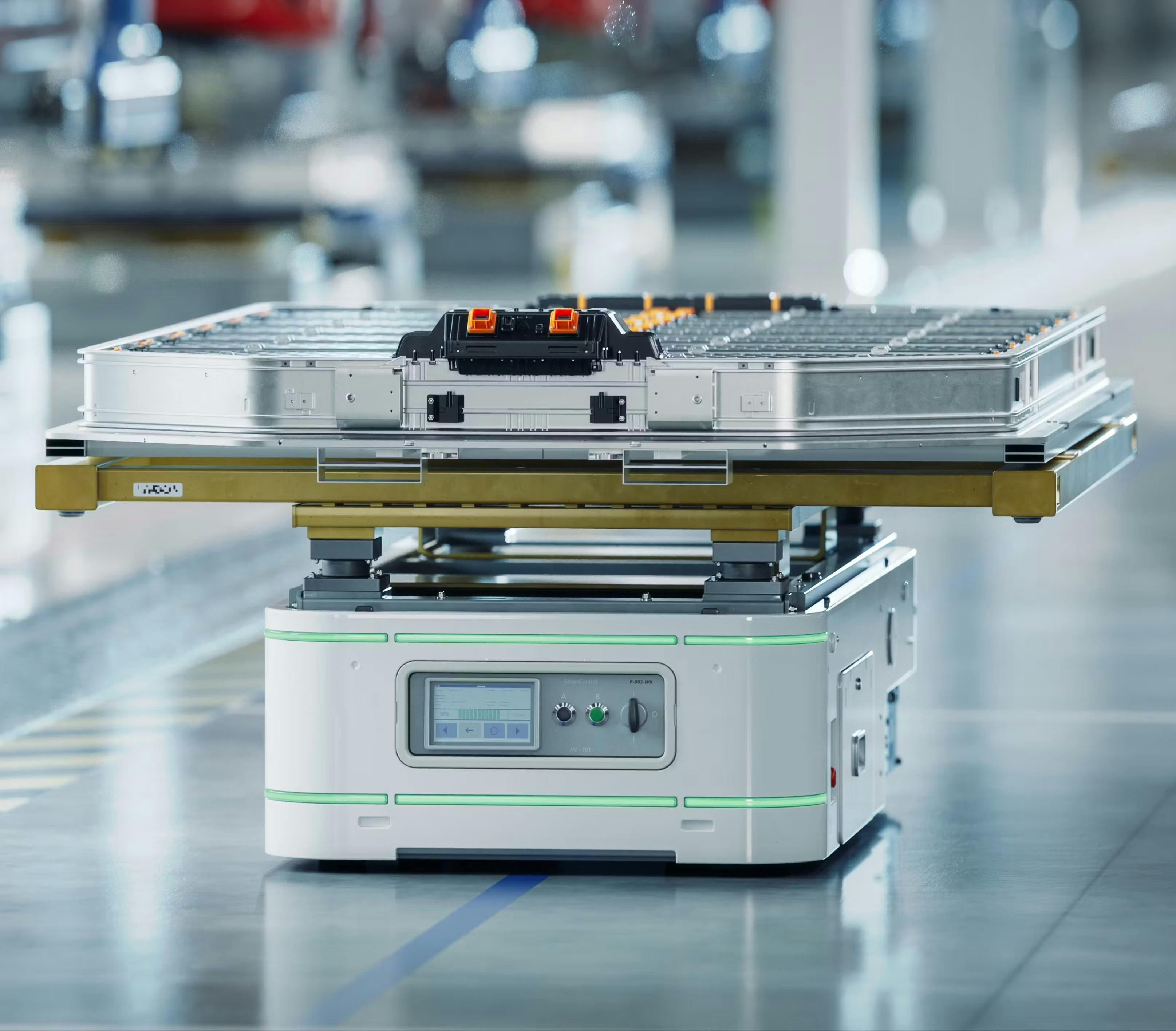

Productivity Monitoring

Real-time monitoring of robot fleet performance, including utilization rates and task completion times. Enables optimization of robot deployment, workload balancing, and rapid identification of process bottlenecks in warehouse and production environments, leading to enhanced productivity and resource allocation.

Key Challenges

Data overload and “finding the needle in the haystack” impeding productive monitoring and troubleshooting.

Limited visibility into gradual efficiency declines and their causes

Ensuring minimal latency in data transmission and processing for timely decision-making.

Our Solution

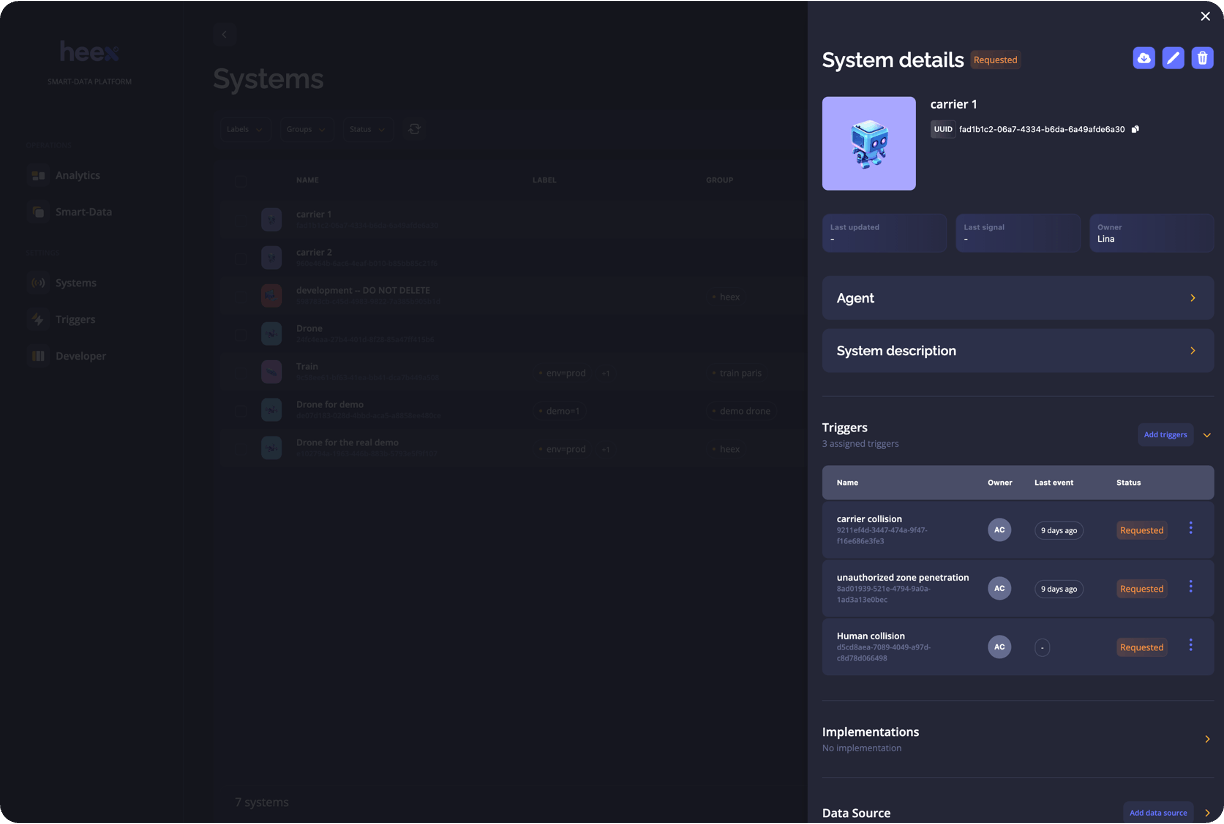

Unique Edge to Cloud Data Loop

Our intelligent software agents are deployed directly on autonomous systems, capturing crucial performance data at the source based on customizable scenarios that can be quickly updated Over-The-Air in split seconds.

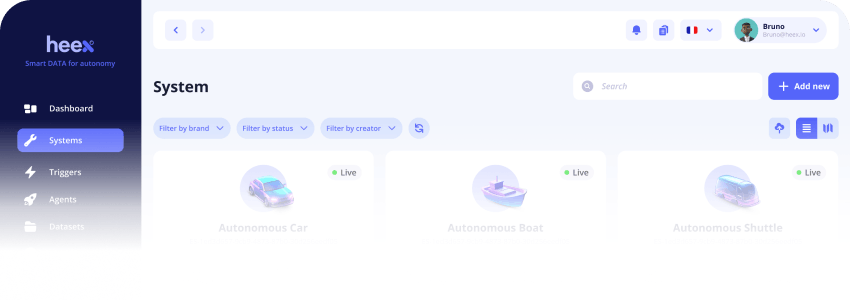

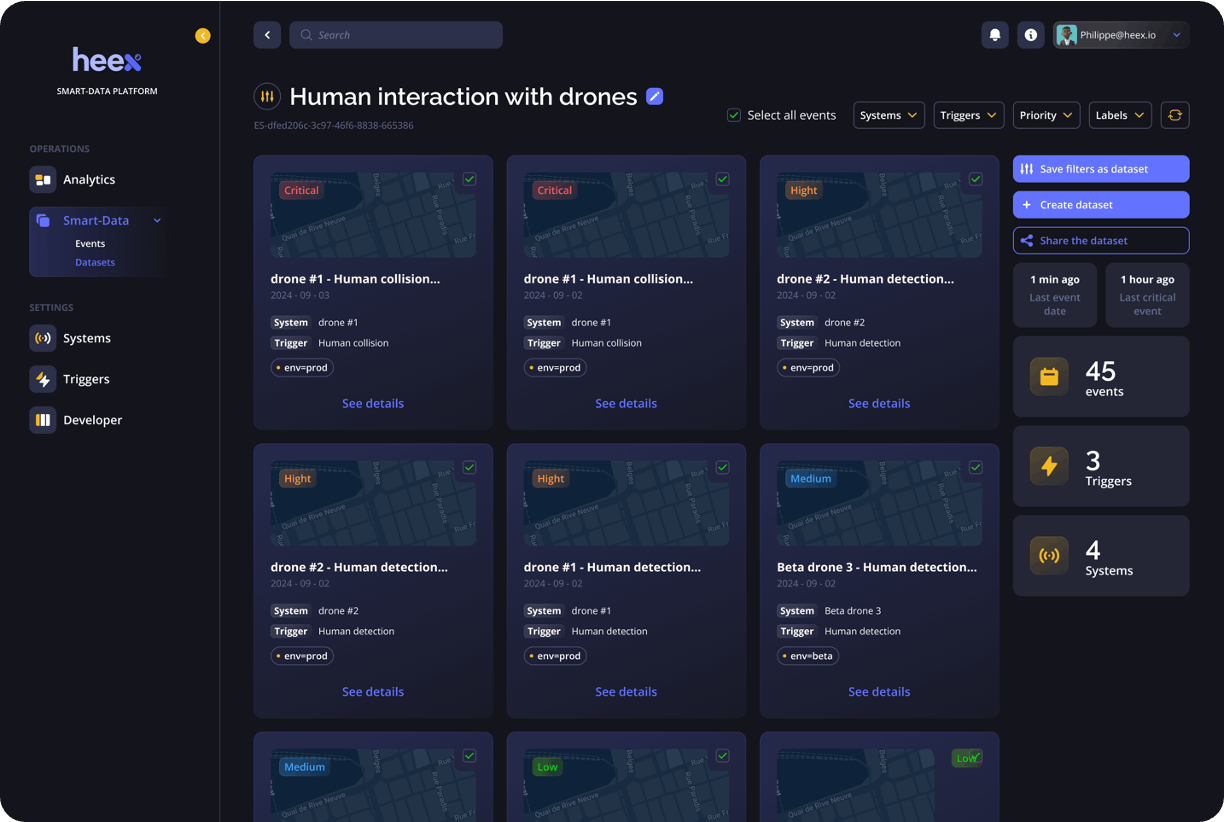

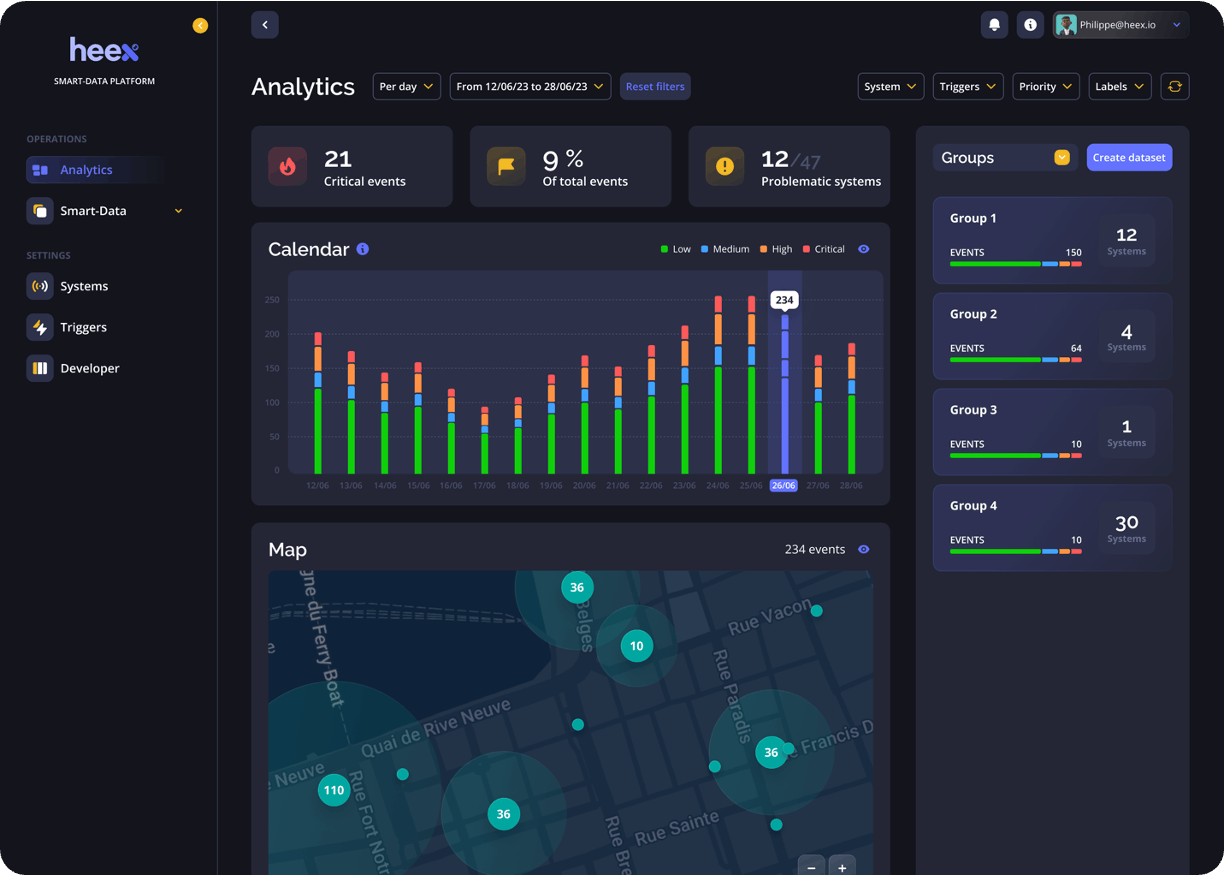

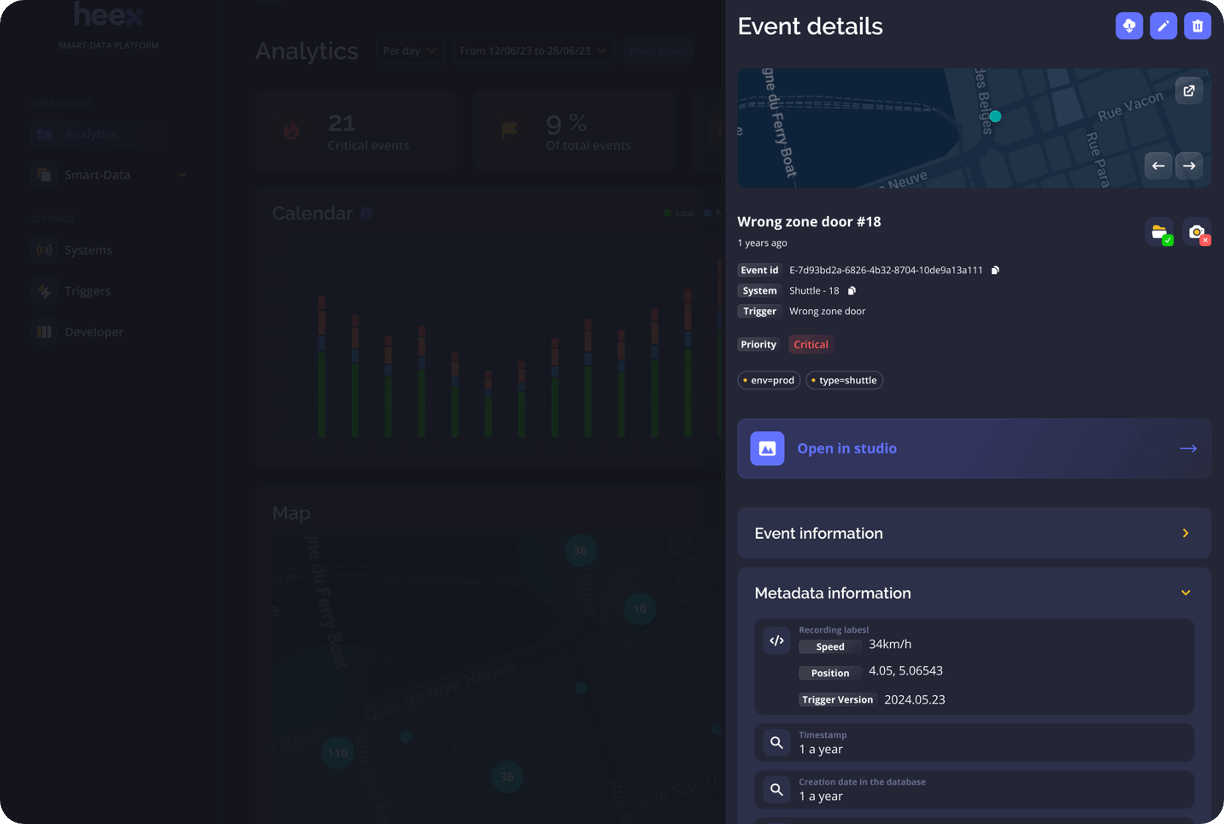

Your Go-To Dashboard

A comprehensive, user-friendly interface that acts as a data control panel across your autonomous system, designed for both technical and non-technical users. It presents key performance indicators (KPIs) and metrics in real-time, allowing managers to quickly assess productivity levels and identify areas for improvement.

Advanced Analytics for Optimization

Leverage data analytics to uncover trends and patterns, enabling informed decision-making to improve process efficiency and product quality.

Seamless System Integration

Integrate effortlessly with existing Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems through powerful Heex APIs, ensuring a unified approach to productivity monitoring and data management.

Benefits

Generate only the data you need, considerably reducing the amount of data stored and processed

improved monitoring and decision-making

Real-time insights regarding system performances

Customer Story

Nokia

"Thanks to Heex Technologies' solution, which includes an intuitive web platform for programming and monitoring event-based road data, we were able to generate metadata from ITS V2X exchanges detected within our 5G edge system. This allowed us to meet the needs of our dynamic geofencing application as part of the 5G Open Road project."

Laurent Roullet - Research department lead at Nokia Bell Labs

Who we serve ?

For SMBs and Enterprise

Scalability

Heex software agents seamlessly collect data from within robots, integrating effortlessly with any robotic control system.

Security

Heex uses OAuth 2.0 for logins, JWT for API authentication, and HTTPS (TLS) for agent-to-cloud communication. This multi-layered approach safeguards our platform against common vulnerabilities.

Modularity

Our highly adaptable software agent framework and SDK supports an unlimited number of deployments across your autonomous fleet. The system's abstraction layers allow for effortless customization, with infinite combinations of triggers and conditions that can be reprogrammed over-the-air directly from the centralized Platform.